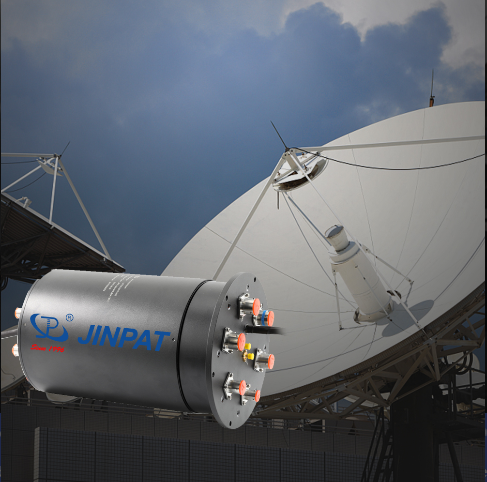

Due to the specialness of the industry, integrated slip rings are one of the important branch. Every slip ring manufacturer has its integrated solutions. JINPAT Electronics as an established slip ring manufacturer with a dynamic R&D team and rich production experience, has a high customization rate. Over 90% of our slip ring products are integrated solutions.

There are a variety of integrated slip rings. The most common one is an integration of electrical slip ring and pneumatic hydraulic rotary joint. Such combination allows pass of both electricity, signals, fluid and gas. As for other, there is integrated rotary joint that transmit fluid/gas and optical signals. Clients can order a custom solution according to their needs.

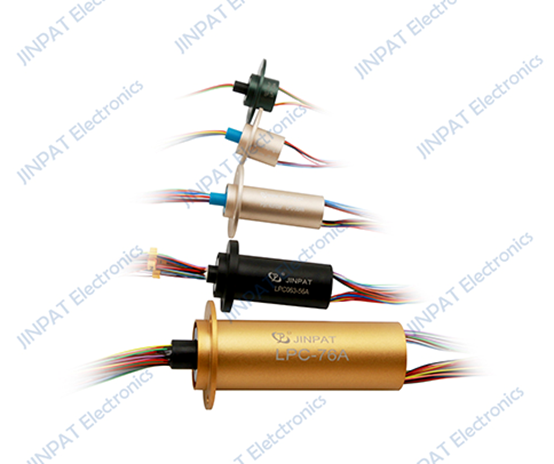

Recently, there are some newly published integrated slip ring models that mixed transmit optical signal and radio frequency signal. LPT000-47S-03E2-HF03 is one of these comprehensive slip rings. This solution is based on a JINPAT independently developed radio frequency rotary joint, HF-03A with 3 channels. Every channel operates at the frequency at 2GHz. This is a radio frequency integrated swivel joints are applied in short wavelength radio equipment. Besides, there are 47 channels for other signals and 3 100M Ethernet signal channels. This slip ring model demonstrates the most common way of combining radio frequency signal transmission and power transmission. It can also work as a radar slip ring solution. To cater such an amount of channels, the size of this integrated slip ring is relatively large. The length of this high frequency rotary joint is 240mm and the diameter is 175mm.

In contrast to the above mentioned solution, LPT000-0215-12S-HF02 is a quite mini-size slip ring. The outer diameter of this slip ring is only 50mm, with tail buckle and SMA connector included, the length only adds up to 85mm. This perfectly show how JINPAT is good at optimizing slip ring structure while keeping its performance in high level.

For more slip ring solutions and products, please contact JINPAT.