Slip rings and rotary joints are important electronic devices that allow signals and power to transmit between stationary part and rotating part. They are very common components that you can find both in industrial production machines and everyday electronic products. In the former articles, we pay more attention to the industrial applications of JINPAT slip rings. Today, we will be looking into a more everyday application of the slip ring products.

With the heat and wide spread of smart home, intelligent lighting system as part of it also becomes a new trend. In the intelligent lighting system, an electrical slip ring or rotary joint is installed to enable the lighting source to rotate in the programmed angles, also the lift and down of the whole luminaire demands the assistance of the slip rings. Slip rings help to rid of the concern of twisted cables and cable tangles to make free adjustment of the lighting possible. JINPAT Electronics provides slip rings for intelligent lighting and luminaires.

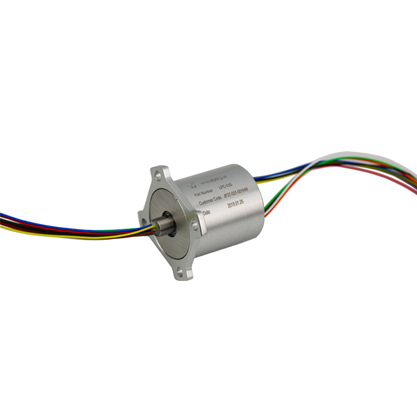

Given the size of the luminaires and projecting head, JINPAT Electronics has different recommendations. For home-used small size luminaires, JINPAT capsule slip rings and miniature slip rings are good choices. These small size slip rings feature small and compact structure with super light-weight. Therefore, they can be easily joint with the luminaire devices without burdening the whole load meanwhile guarantee a smooth 360-degree rotation and reliable signal transmission.

As for lighting systems that concern a more powerful projector and high demand of data transmission, JINPAT Electronics recommend the through bore slip ring and flat slip ring. Clients can also request an integrated solution that enable high definition video signal transmission. The custom solutions prove very practical within the lighting system that supports HD video. More optional signals include SDI, USB and so on.

JINPAT Electronics has provided verified rotary transmission solutions for clients at home and abroad. Our technical team is very experienced and innovative. Contact JINPAT for more slip ring solutions!