High definition signal slip ring is one of the most widely applied slip rings. Generally, they are integrated with other slip rings and rotary joint to attain better and more diverse function. JINPAT as a historical slip ring manufacturer, has done a lot of R&D related to slip ring with high definition video signal capacity. The JINPAT high definition video signal slip rings basically branch into two types: slip rings for computer high definition video signal slip ring that transmit signal like DP signal and HDMI signal; the other is those hybrid slip ring with SDI signal capacity. The most salient difference between the two is their different choices of cables.

SDI slip ring adopts coaxial cables, while DP slip ring and HDMI slip ring adopt several groups of twisted pairs. However, there are different choices of the cables regarding the different version and definition rate of the video signals. Take HDMI signal transmission for example, if a slip ring is to transmit HDMI1.3, cables should be matched to enable the transmission. The same is true with SDI slip ring, cable should be compatible with the slip ring unit and the signals.

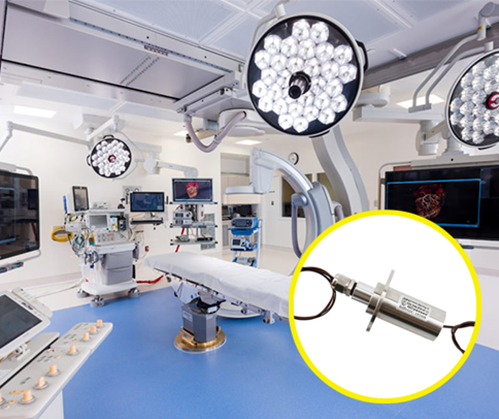

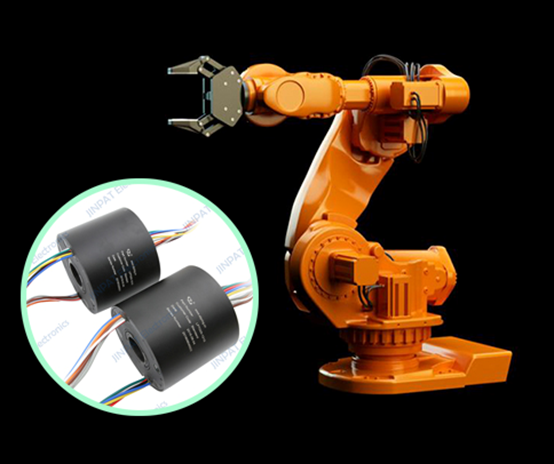

Aside from the differences in cables, the two branches of slip rings also serve different applications. Take DP/HDMI high definition video signal slip rings for instance, they are frequently used in multimedia electronic devices. As for SDI slip rings, they can transmit only high definition video signals but not audio signals. Therefore, this kind of slip ring are mainly applied in high definition surveillance system, industrial machine vision, pipeline inspection robot and military optical devices.

JINPAT Electronic, with years of devotion in the slip ring industry, has developed numbers of high definition video slip rings. JINPAT SDI slip rings have the largest production volume. A reason is that SDI slip ring is the best rotary transmission solution for industrial machine vision and military high definition tower crane cabin. And given the technical complexity and cost of the HDMI/DP slip ring, it basically still stay in the military and high-end market.