As a significant component of modern manufacturing, the demand for High Current slip rings in the shipbuilding industry is steadily increasing. Almost all modern vessels are equipped with navigation radars, making High Current slip rings indispensable components for marine navigation radars. Furthermore, some specialized ships are equipped with mechanical inertial navigation systems, which also incorporate High Current slip rings.

Typical application terminals for High Current slip rings are found in large engineering ships’ crane and hoisting equipment, as well as in special-purpose ships employing full-rotating electric propulsion systems. As a leading player in the international slip ring industry, JINPAT has developed hundreds of products for these two types of equipment, with most of them being high-voltage and High Current models. Some propulsion systems even utilize High Current slip rings with power ratings reaching several tens of megawatts. Taking the example of crane and hoisting equipment on engineering ships, whether it be specialized floating crane vessels for offshore operations, ships with deck cranes, wind turbine installation vessels, or hoisting equipment on offshore oil drilling platforms,JINPAT high-voltage and High Current slip rings have extensive applications.

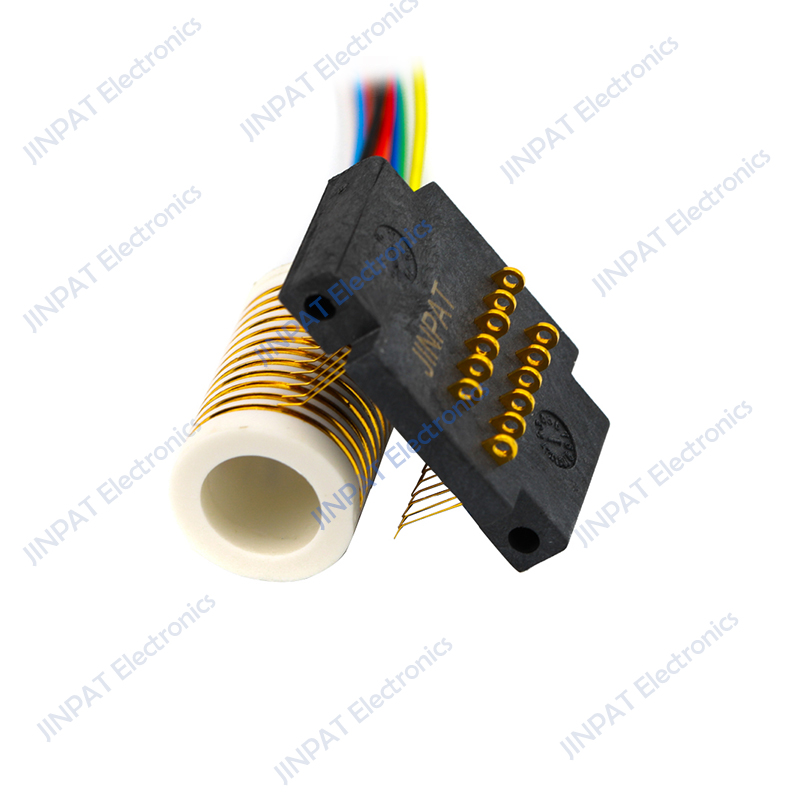

Typically, smaller lifting weight shipboard cranes adopt single-function High Current slip rings that do not integrate weak signal modules or pneumatic and hydraulic modules. Among the slip rings produced by JINPAT for marine crane applications, this type is the most common,featuring a box-type structure where the stator and rotor are independently housed in a single enclosure. On the other hand, regular shipboard slip rings usually employ ordinary steel materials for the casing with relatively lower protection ratings.

However, for certain special equipment like crane slip rings used on oil drilling platforms, 304 stainless steel orhigher-grade steel materials are utilized, and the thickness of the plate is several times that of the casing used in regular crane slip rings, enabling the product to meet specific explosion-proof ratings. Therefore, slip rings with explosion-proof capabilities have higher protection ratings. A few shipboard High Current slip rings for marine crane applications may adopt a cylindrical integral structure, which facilitates achieving higher protection ratings.

As for propulsion system applications, JINPAT offers a variety of products, including regular single high-power modules and multi-module slip rings integrating High Current modules, pneumatic and hydraulic slip rings, and electrical signal slip rings. In specialized slip rings for propulsion systems, there is a category of products characterized by ultra-high operating voltages, usually exceeding 3300VAC, with tremendous power transmission capabilities, often exceeding one megawatt. JINPAT has successfully delivered multiple specialized slip rings with power transmission capacities of up to 7.5 megawatts and has the capability for research,development, and mass production of specialized slip rings with a maximum power of 15 megawatts.