In marine lifting operations, the rotating function of the crane is crucial. This not only enhances the flexibility and stability of the crane but also allows the crane to adjust its angle and direction flexibly during the operation to meet different lifting requirements.The offshore crane slip ring acts like a precision current transmitter,enabling the free rotation of the inner rotating ring through its structure and functionality, thus achieving this critical goal.

The basic principle of the key component,the offshore crane slip ring, is to use the close combination of the conductive ring groove and brushes to achieve the crane’s rotational motion through the transfer of electric current. Its construction is mainly divided into inner and outer rings, with the outer fixed ring secured to the crane’s base, while the inner rotating ring is closely connected to the outer fixed ring, allowing the crane to achieve a 360-degree rotation. Compared to land crane slip rings, the offshore crane slip ring has some special advantages. It can achieve full-range rotation of the crane, making it more flexible in dealing with various complex working conditions in offshore lifting operations.

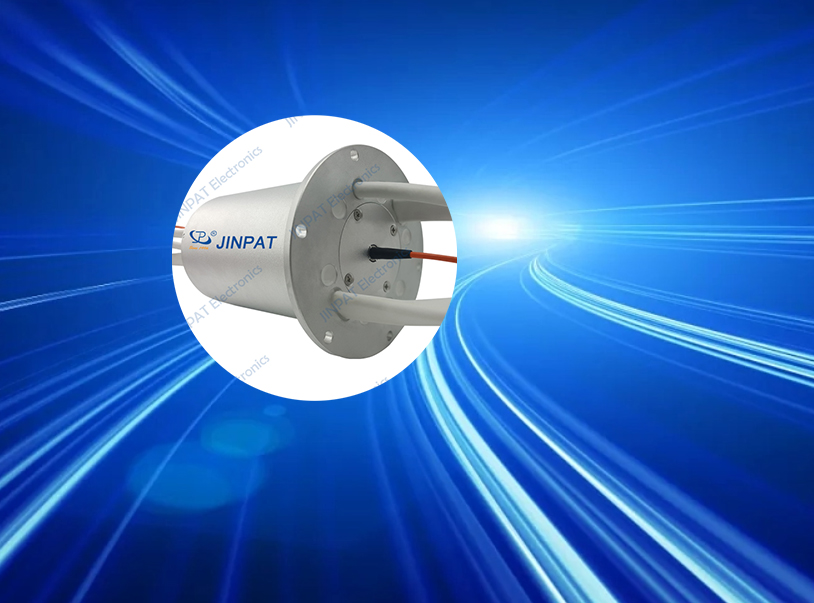

The newly developed LPA000-09800-03200-01PEslip ring by JINPAT possesses a series of features and advantages suitable for various environments and power standards. The slip ring has excellent heat dissipation capabilities, ensuring high performance under high load conditions.Its support for multiple large currents makes it suitable for various power requirements. With a protection rating of IP54, it can resist the intrusion of dust and water, ensuring long-term reliable operation. Even in complex marine environments or harsh working conditions, it performs well, maintaining stable operation and adapting to various climate conditions. In high humidity environments, its performance remains excellent, with a relative humidity of up to 95%, catering to different application needs. The slip ring is suitable for different rotational speed requirements from 0 to 5 rpm, offering multiple voltage and current options to meet various power standards.

Whether your application is horizontal orvertical, JINPAT slip rings can work stably and reliably. The stability and reliability are ensured by bottom and top bolt fixing, especially suitable for vertical applications such as hoisting. Regular maintenance can extend the life of the slip ring, reduce maintenance costs, and provide long-term support foryour equipment.

With nearly 30 years of history, JINPAT has focused on the slip ring industry and accumulated strong research and development capabilities. When you need a reliable electronic slip ring solution, JINPAT provides the right choice for you.