Wind power slip rings play a crucial role in wind power equipment, serving as a key medium for electrical power transmission and control. The wind power slip ring is responsible for connecting the rotating part of the wind turbine generator with the stationary part, allowing the transmission of power signals, control signals, and data during rotation. The stability of slip ring operation is directly related to the performance and reliability of wind power equipment.

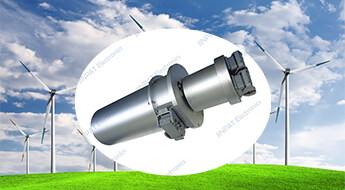

JINPAT has developed a new slip ring, the LPW000-0740-06S, specifically designed for the field of wind power. This slip ring combines reliability with high efficiency, featuring an IP54 protection level. It adopts connectors (such as Harting connectors) to replace traditional lead-out designs, simplifying the installation process. The built-in heating system can maintain a temperature of 20°C, ensuring an appropriate temperature difference with the external environment. Waterproof and breathable valves are equipped at the top and bottom to ensure dynamic pressure balance between the internal and external environments, preventing condensation and further enhancing stability in harsh conditions. This slip ring for wind power equipment,through specialized design and performance optimization, provides a reliable and efficient power transmission solution for wind power generation systems.Compared to other slip rings, it stands out in adapting to complex working environments and improving system reliability.

JINPAT LPW000-0740-06S slip ring demonstrates significant advantages over ordinary performance slip rings in several key aspects. Firstly, it possesses high-speed and high-current transmission capabilities, meeting the demands of high-speed rotation and high-power transmission of wind turbine generators. Secondly, it is designed for harsh environments, including outstanding resistance to conditions such as wind erosion, high humidity, and extreme temperatures, ensuring stable performance in the demanding working environment of wind power equipment. Additionally, the slip ring for wind power equipment emphasizes low-noise design, contributing to reducing the vibration and noise generated by wind turbine generators during operation. Most importantly, this slip ring has outstanding reliability and a long service life, reducing maintenance frequency and costs. Equipped with waterproof breathable valves, the product can prevent the intrusion of external particles and moisture, thereby reducing friction and wear.

JINPAT offers various types of slip rings.If you need more slip ring solutions, feel free to contact us. JINPAT is dedicated to providing you with the best solutions and slip ring products.

.jpg)

.jpg)