Among all electrome chanical products,except for a few areas where slip rings require thousands of components, the majority of slip rings used in these fields are not very complex products.Apart from bearings, brushes (carbon brushes), and wires, the number of components in other parts of the slip ring is relatively small. There are also many processing techniques for these parts, including injection molded parts,stamped parts, pressure (casting) castings, and machined parts. The most commonly used slip ring models are injection molded parts. The capsule hollow shaft series standard slip ring with the highest annual production and sales volume of JINPAT uses a large number of injection molded internal and external components.

Stamped parts, on the other hand, are mainly made of slip ring shells. The standard micro and ultra micro slip rings of JINPAT use stainless steel shell stamped parts. The use of stainless steel shell stamped parts can significantly improve the impact resistance and other performance of the slip ring. The same principle applies to using die castings as the outer shell of slip rings. Due to the harsh working environment, most of the engineering machinery slip rings developed by JINPAT are mainly made of die castings.

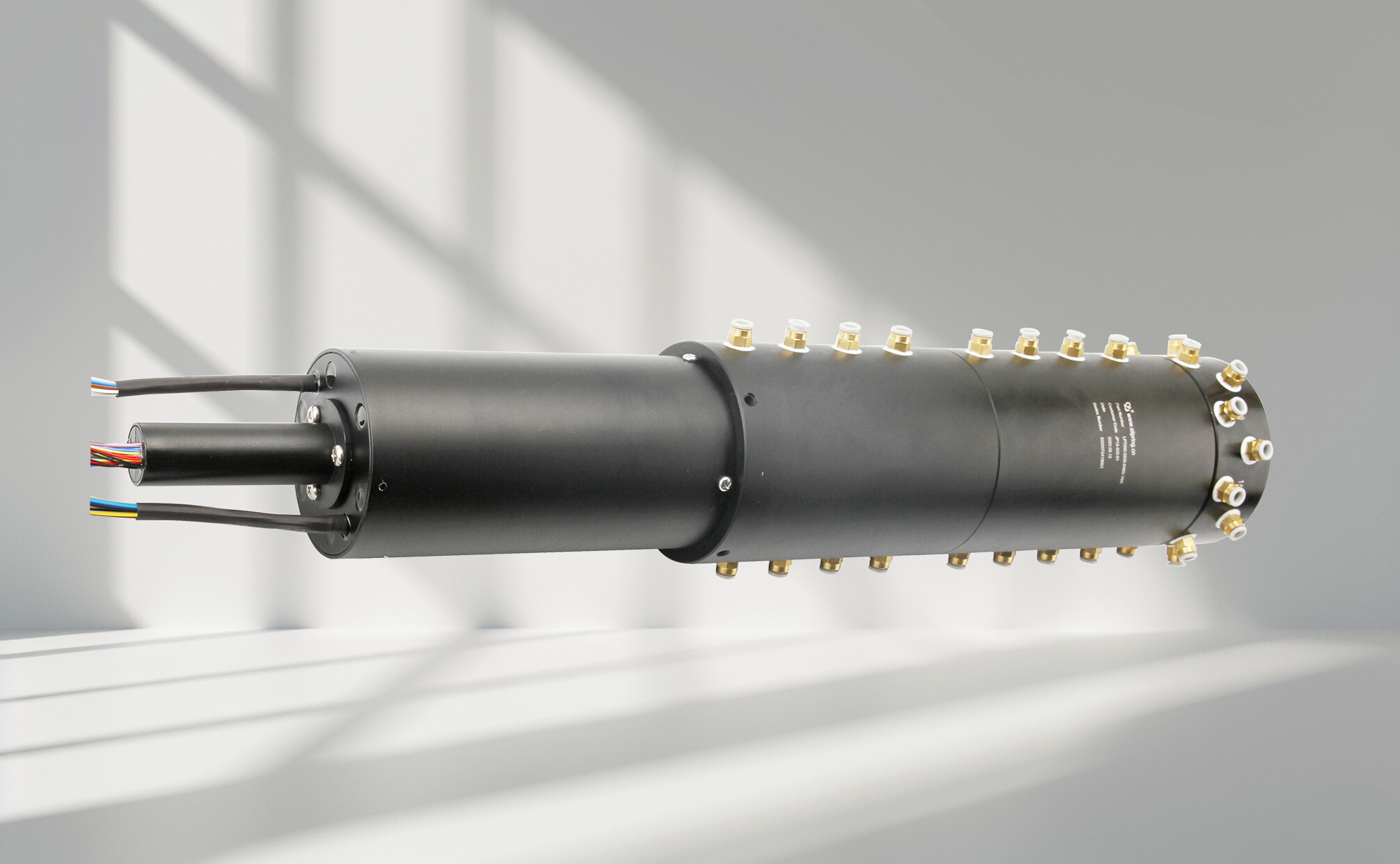

The large-scale use of machined parts as stator and rotor components for slip rings includes gas-liquid slip rings,fiber optic slip rings, high-frequency slip rings, and some customized slip rings. Among them, the standard model of the JINPAT gas-liquid series slip ring mainly uses aluminum alloy material for its main components, while its customized version mostly uses steel. Therefore, in general, the customized version of the JINPAT gas-liquid slip ring weighs much more than the standard model, and of course, it can withstand much greater gas-liquid pressure.

Let’s take a look at fiber optic slip rings and high-frequency slip rings. Whether they are standard products or customized products, the main components of the stator and rotor of these two types of slip rings are made of stainless steel material. However, due to the different transmission media, the internal structure of these two products may also be slightly different. For example, high-frequency slip rings do not require a speed exceeding 100rpm, while the speed of fiber optic slip rings may reach 20000rpm.Therefore, the requirements for machining are not the same. Obviously, due to the higher speed of fiber optic slip rings, their requirements for machining are also higher.