At 10:00 am on August 20th, Beijing time, Black Myth: Wukong, the only purely domestically produced 3A game in China, was launched globally. Prior to this, both the hot searches and the capital market had set off several climaxes, which was also a big shock to other industries. However, some overseas reviewers also pointed out that they did not understand the storyline and historical background of Journey to the West, so some reviewers mentioned: I was confused if I couldn’t understand the story, and I needed to make up for it in advance. However, if Chinese culture wants to succeed overseas, it cannot be accomplished by one industry or one company.

The launch of “Black Myth: Wukong” will undoubtedly allow more domestic companies to invest in high-budget, high-quality game development, promote innovation and competition in the entire industry, prompt them to improve their production level and pursue higher industry standards, which also indirectly means that the demand for high-end gaming equipment and simulators will increase significantly.

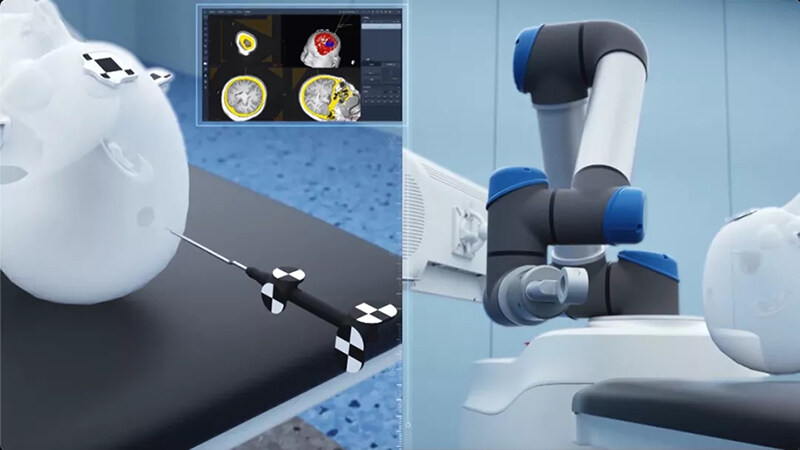

The innovation and complexity of gaming equipment require slip rings with higher precision and durability to support rotation control and signal transmission, thus increasing the market demand for slip rings. In addition, this growth in demand will prompt slip ring manufacturers to develop more professional solutions for gaming equipment. As a company that has been committed to the forefront of domestic conductive slip rings, JINPAT has produced many products for gaming equipment: used in racing cars and flight simulators, providing stable signal transmission for the rotating part of the flight control joystick; designed a number of VR-specific slip rings for overseas VR equipment manufacturers, whether large or small devices, there are corresponding solutions; in high-end game joysticks that require complex rotation, JINPAT slip rings provide stable power and data transmission.

Due to the boom in high-end gaming devices and simulators in the market, some slip ring manufacturers may cooperate more with gaming hardware manufacturers, VR/AR device developers, etc. to jointly develop innovative products with integrated slip ring technology to promote business growth for both parties. In general, although the application of conductive slip rings in the gaming industry is relatively niche, its role in high-end gaming devices cannot be ignored. With the development of gaming technology and the increase in market demand, JINPAT Electronics has the opportunity to achieve its own growth through technological innovation and market expansion.