In the first half of 2024, with the release of Apple Vision Pro, the AR/VR headset market has been injected with new vitality!At the same time, products such as Ray-Ban Meta and Apple Intelligence are leading a new wave in the AI terminal market. In addition, the launch of Vision Pro has also spawned a new market segment – mixed reality (MR) headsets. It combines the technical advantages of VR and AR, creating a new form of head-mounted display.

It must be mentioned that the conductive slip ring plays a key role in this technological advancement. It can ensure the stable operation and accurate data processing of the head-mounted display device by realizing efficient power and signal transmission between rotating parts and static parts.

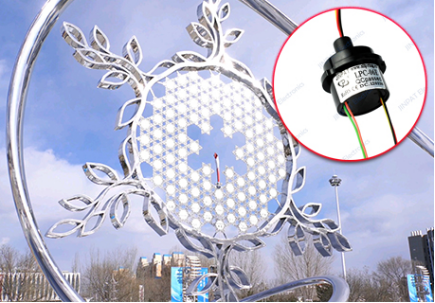

Currently, many VR devices on the market still rely on dedicated cables to transmit information, which to some extent limits the flexibility of the device and user experience.In order to solve these problems, conductive slip rings came into being, which are specially used to solve the problem of winding during the rotation of equipment. It plays an important role in mechanical and electrical equipment with high technical content and has become an indispensable connector for many electrical equipment.

In the VR industry, the application of conductive slip rings is particularly important. As a magic tool to solve the problem of wire restraint, conductive slip rings enable VR devices to rotate freely, greatly improving the flexibility of the equipment and user experience. JINPAT has designed a number of VR special slip rings for overseas VR equipment manufacturers, and has corresponding solutions for both large and small devices. For example, the conductive slip ring designed by JINPAT for VR swivel chairs integrates high-definition video signal pathways and USB2.0 signal pathways, supports video signal transmission up to 4K@30Hz, solves the problem of wire winding during rotation, and enhances sensory experiences such as touch, making VR devices more comprehensive in terms of vision, touch, and hearing. Stimulation.

With the continuous development of the VR industry, the evolution of equipment from static to dynamic and from simple to complex is an inevitable trend. In this process, professional VR conductive slip rings have become an indispensable technical component. JINPAT has not only developed different types of combined conductive slip rings and special signal slip rings for small and medium-sized equipment, but also developed large integrated conductive slip rings that integrate multiple high-power channels, high-definition video signal channels and other signal channels for rotating ultra-large VR dynamic theater systems. These innovative solutions have greatly improved the power and signal rotation transmission capabilities of the equipment, and promoted the further development and application of VR technology.