Through bore slip rings have the second largest production volume among all JINPAT products. This type of slip rings is broadly applied in various industry and people’s everyday life. Radars as a radio detection equipment, are also a major application of slip rings. In the civil field, slip rings are installed in aircraft, ships and for weather forecast. And given the different application scenes, slip rings are different.

In some low peak power radar systems for short distance detections, most are through bore slip rings with small through bore and small diameter. JINPAT Electronics has provided couples of slip ring solutions for the civil-used radar systems. JINPAT standard through bore slip ring models can fit such needs. The most representative models are LPT012-0610, LPT038-1205 and LPT038-0605.

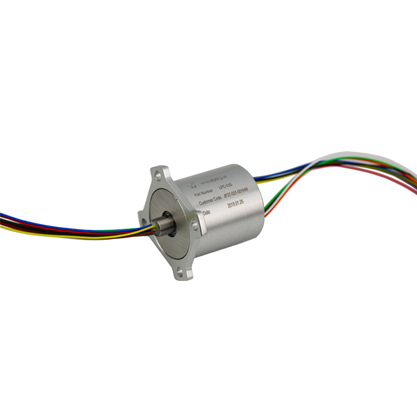

Generally speaking, standard through bore slip rings are cost-effective products. However, for some high-end radar systems, a custom integrated slip ring is needed. Radar system with high peak power, generate a large volume of data. And recent years has witnessed the integration of radar and computer technology. Slip rings that transmit 100M Ethernet signals and Gigabit Ethernet signals are ubiquitous. LPT000-36S-E2 is an Ethernet integrated slip ring with 36 signal channels and 1 100M Ethernet signals.

Some large radar systems with higher data capacity, an integrated slip rings with single Ethernet channel are not sufficient. And radio frequency rotary joint, also known as high frequency slip rings are key components to facilitate data transmission. LPT000-0315-0810-80S-E3-HF03 and LPT060-0630-18S-E2-HF04 are two radio frequency and Ethernet integrated slip ring models that are well-received among customers.

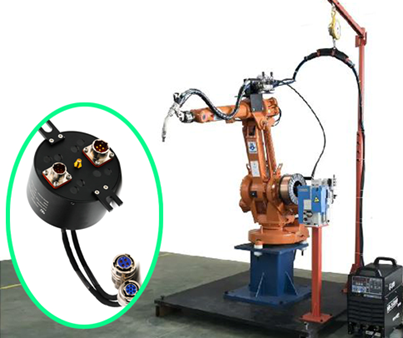

Most JINPAT hollow shaft slip rings adopt traditional precious metal or fiber brush friction pairs. And on some large radars, the slip rings are directly installed on the rotation shaft. As for radar with larger shaft diameter, radio frequency signal is not enough to cater data transmission. To fulfill requirements of this type of radars, JINPAT develops radar slip ring with silver carbon graphite friction brush. This slip rings adopt aviation connector to facilitate installation and maintenance of slip ring cables. As a pioneer in the slip ring industry, JINPAT Electronics also develops multi-channel integrated slip rings, integrated flat slip rings and so on for various radar systems.