JINPAT Electronics is one of the few civil-run slip ring manufacturers that have the capacity of developing high tech slip ring. JINPAT independently developed two-channel radio frequency slip rings. And these JINPAT High Frequency Slip Rings excel in mechanical and electrical performances. Beside, JINPAT Electronics also won plenty of key technology patents in related to high capacity radio frequency slip ring and high-definition video signal and high frequency signal rotary joint. JINPAT Electronics takes pride in its innovative ability and product performance.

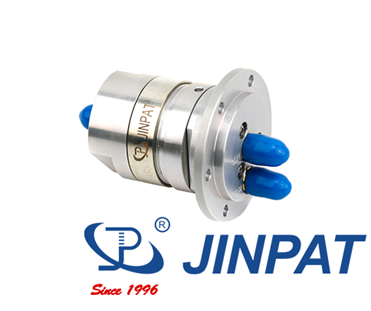

To catch up with the market’s need, JINPAT Electronics also further integrates the LPCC high frequency slip ring with the LPC-T capsule slip ring, and codes the new integrated slip ring as LPC1C standard slip ring. JINPAT LPCC radio frequency slip rings, with choices of cables with different impedance to allow transmission of radio frequency signals and SDI high-definition video signals. JINPAT LPC1C is therefore able to enable rotary transmission of power and signals on some photo-electrical globe and similar devices.

LPC1C is of the mini slip ring type, and the electrical part only supports 1 2A power channel. At the choice of cable with 50Ω impedance, the peak power and average power of the radio frequency signals are limited. Another more popular solution is based on the LPHF series. LPT000-1205-HF01 is a newly published custom slip ring. This custom solution is based on JINPAT Through Bore Slip Ring series. As for the radio frequency module, there is an integrated single channel RF rotary joint LPHF-01C. This rotary joint works at 18GHz with a peak power of 3000W.

LPT000-0215-12S-HF02 is the other new slip ring model. Such radio frequency slip ring features super compact and well-laid structure. With an integrated 2-channel radio frequency rotary joint, the outer diameter is kept within 50mm and the height are only 60mm. In its electrical part, there are 2 15A power channels and 12 signal channels. And the voltage is 24VAC. To integrate such a complex and well-functioning structure in a limited space is very challenging in technology. And JINPAT managed it.

For more information of JINPAT radio frequency rotary joint you can send us an enquiry.