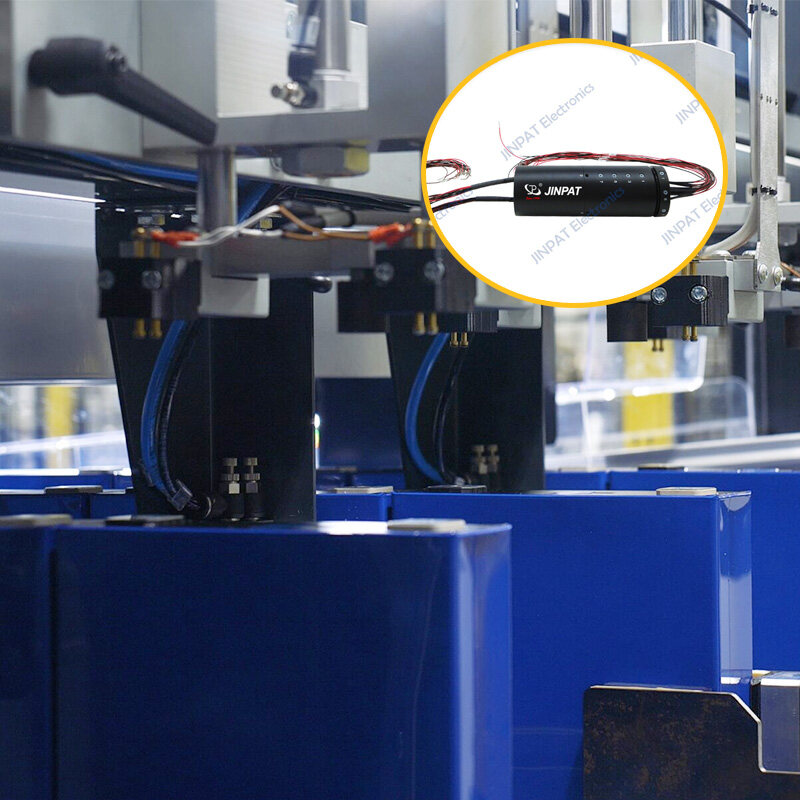

As the lithium battery manufacturing process requires increasing inspection accuracy and equipment automation, system integration has become an important direction in equipment design, and the multi-functional slip ring LPPL022-2403-08A introduced by JINPAT, with its integrated electrical and gas transmission design, provides efficient, stable and space-saving rotary connection solutions for lithium battery inspection equipment, and assists in the continuous upgrading of intelligent manufacturing. It can help the smart manufacturing to upgrade continuously.

Multi-functional integration, more compact structure

LPPL022-2403-08A slip ring has the function of synchronized rotary transmission of electricity and gas, integrating the traditional split structure into one, effectively saving the installation space of the equipment, especially suitable for lithium battery testing equipment, industrial robots, rotary stations and other application scenarios that require high space utilization rate.

Second, reliability enhancement, strong anti-interference ability

Through the integrated closed design, the slip ring unifies the management of electrical signals and gas channels, effectively reduces the impact of the external environment on transmission stability, reduces the risk of potential failures such as gas leakage and electrical contact interference, and significantly improves the stability and service life of the testing equipment.

Third, highly adaptable to automation control system

In the lithium battery testing process, the equipment needs to complete a series of coordinated actions such as clamping, rotation, pneumatic drive, signal transmission, etc. LPPL022-2403-08A supports a variety of current and gas channel configurations, compatible with the mainstream automation control systems, to help users easily realize the rotary interconnections of complex functional modules.

LPPL022-2403-08A is an electropneumatic integrated slip ring designed for space-constrained, high-precision and multifunctional transmission needs. It not only optimizes the structure of the equipment and improves the automation efficiency, but also guarantees the continuous and stable operation of the system with high reliability, which is an important core component for the intelligent upgrade of lithium battery testing equipment.