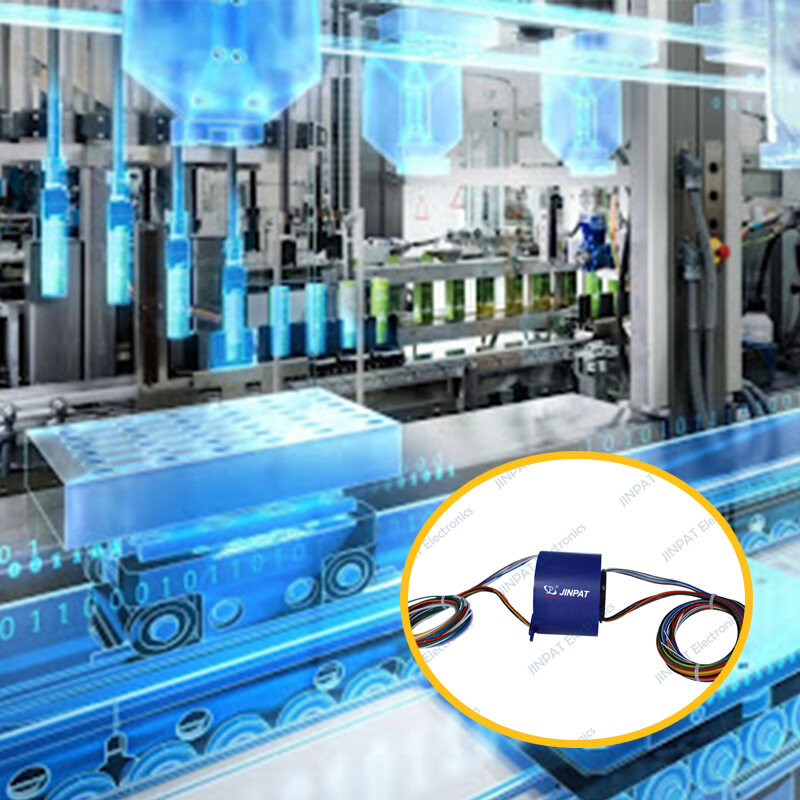

Model: SPT050-104-1210

Application areas: automation equipment, customized rotary modules, light load rotary platforms, etc.

SPT050-104-1210 is a lightweight slip ring designed for automation systems. It adopts plastic open-molded structure, which combines cost control and functionality, and is suitable for applications with limited space or weight sensitivity. The product has good flexibility and adaptability and is suitable for rotating equipment with customized requirements on the number of loops, electrical parameters and structural layout.

Structure and Material

Plastic housing molded in one piece

The product shell is manufactured by plastic molding process, which effectively reduces the overall weight and manufacturing cost under the premise of meeting the structural strength, and is suitable for batch integration. The material selection takes into account the low-temperature working conditions, and the lowest working temperature of the product can reach -40℃, which extends its range of use in cold environments.

Spindle and brush holder modular design

It supports modular spindle and brush holder splicing structure, and the number and length of loops can be flexibly adjusted according to the needs of different projects, which is convenient for customers to carry out system integration and parameter customization, and improves versatility.

Electrical Performance

Operating voltage: 500VAC/DC max.

Compared with conventional molded case slip rings, this product supports higher operating voltage levels to meet the power transmission needs of some industrial equipment with medium to high voltage requirements.

Operating speed: 0~400rpm

The operating speed is higher than that of similar slip ring products, which meets the stability of signal and power transmission under high-speed rotation.

Application Value

Suitable for light load automation equipment, sensing platforms, rotary actuators and other working conditions that require lightweight structure and flexible loop configuration;

Its splicable design significantly reduces inventory pressure and selection costs, and improves production and assembly efficiency;

With a certain degree of high and low temperature adaptability, it can still maintain stable operation under extreme climatic conditions;

For cost-sensitive projects, the slip ring provides a cost-effective solution, especially suitable for large-scale deployment.

The SPT050-104-1210 slip ring is one of the balanced solutions for automation equipment engineers in pursuit of structural flexibility, cost control and reliability. For higher loop counts, electrical interfaces or structural dimensions, we can provide customized versions, please contact our technical team for detailed selection information and sample support.