Precision conductive slip rings can be classified into many types, with different manufacturers having different standards and definitions. However, generally speaking, the classification methods are mostly similar. Firstly, they can be categorized based on structure. This type of precision slip ring generally refers to conductive slip rings with high internal space utilization and very small volume, such as the LPMS series slip rings from JINPAT. Another category is the technically intensive precision slip rings, which include fiber optic slip rings,high-frequency slip rings, etc., and are included due to their high development difficulty. Then, they can also be classified based on the functions of the slip rings. This type of precision slip ring not only has the ability to transmit power but also has one or more functions such as gas, liquid, orsignal transmission.

As a professional and veteran slip ring manufacturer, JINPAT has been in the industry for nearly 30 years. As early as 2002, they established their own technology research and development center,placing great emphasis on cultivating independent research and development capabilities. They are also very skilled in the development of precision slip rings. Regarding fiber optic slip rings, which have very high technical content and excellent application prospects, JINPAT started its independent research and development early. In 2009, JINPAT successfully developed fiber optic slip rings with independent intellectual property rights.

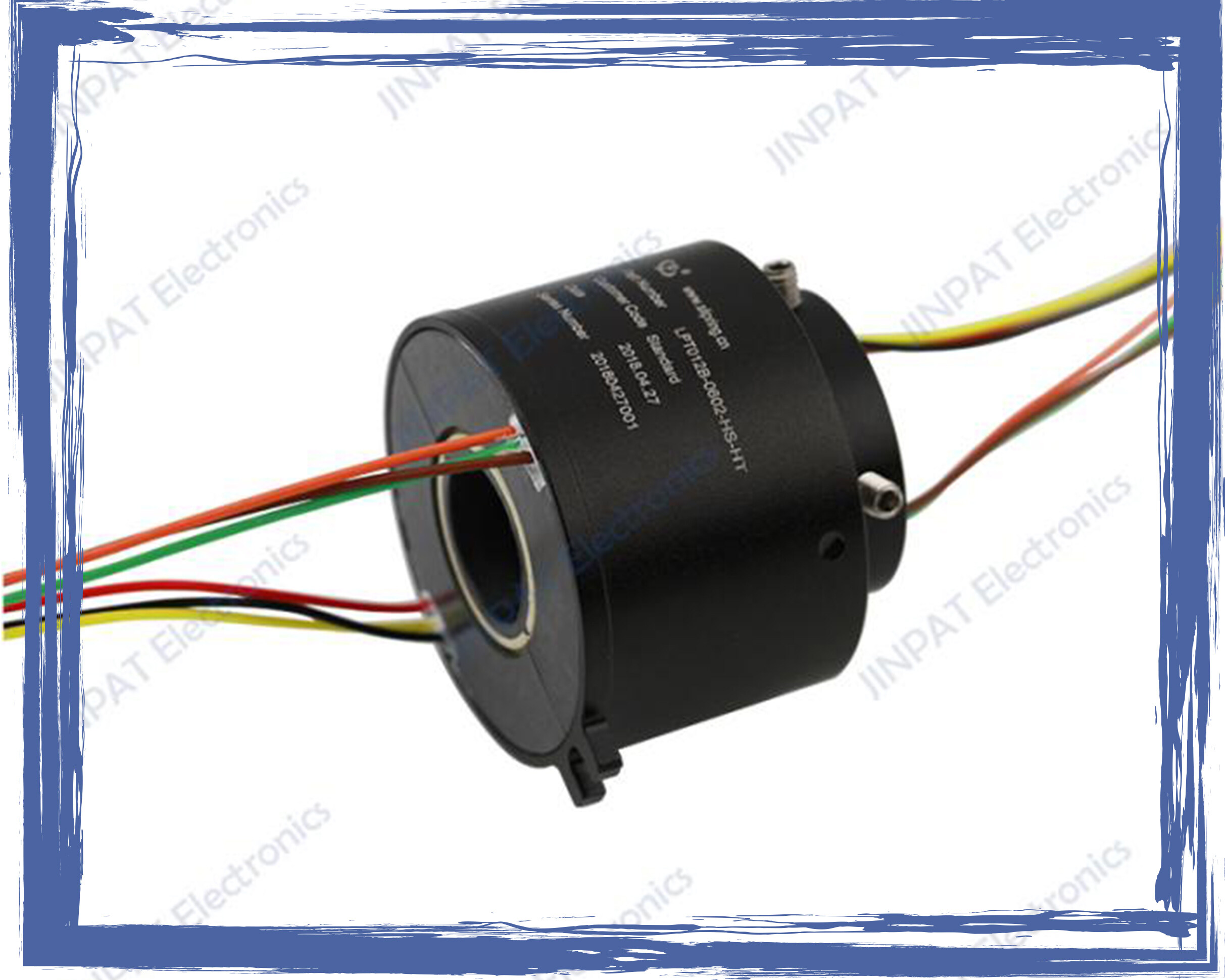

As one type of precision slip ring, fiber optic slip rings have their own uniqueness. Firstly, fiber optic slip rings do not transmit electricity, gas, liquids, or other media; they only transmit light. For example, among the seven colors of light commonly seen in daily life—red, orange, yellow, green, blue, indigo, and violet—some of the light can be transmitted through fiber optic slip rings at the corresponding operating wavelengths. JINPAT’ developed fiber optic slip rings use single-mode or multi-mode fibers, covering a wavelength range from 650nm to 1650nm,corresponding to visible light and near-infrared light.

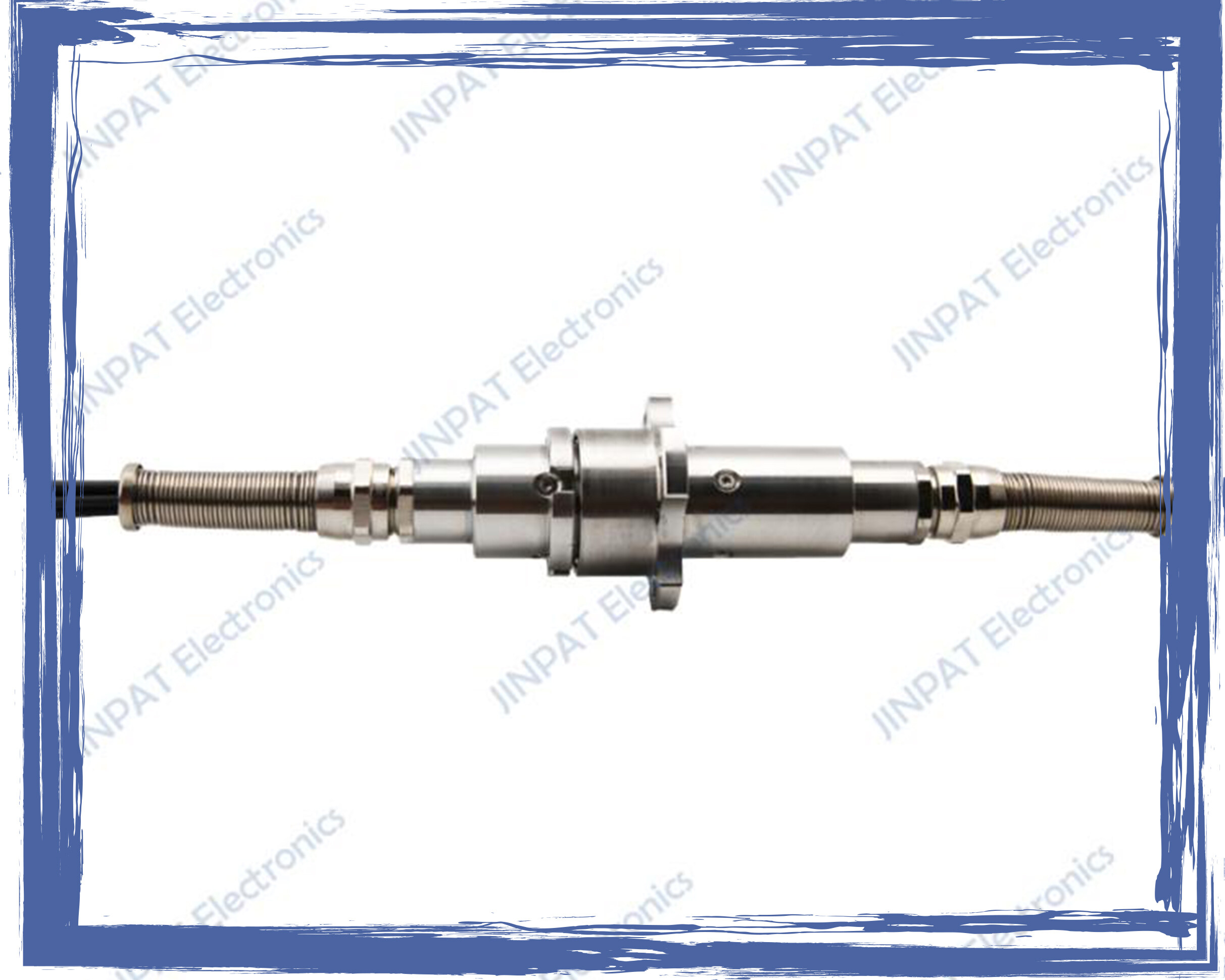

Since fiber optics are transmitted, fiber optic slip rings do not require electronic components but only optical components. Because these optical components need to be optically coupled with single-mode fibers with core diameters as small as 9 or 10 micrometers and multi-mode fibers with core diameters of 50 or 62.5 micrometers, the volume is extremely small, requiring extremely high installation accuracy. This makes the manufacturing and processing of fiber optic slip rings very difficult, which is also the main reason for the high precision of fiber optic slip rings. Due to the high difficulty in internal component processing and the extremely high requirements for manufacturing precision technology, there are not many slip ring companies like JINPAT that can independently develop and manufacture fiber optic slip rings.

JINPAT is committed to developing exclusive slip ring solutions for customers. If you have any slip ring requirements, please feel free to contact us.