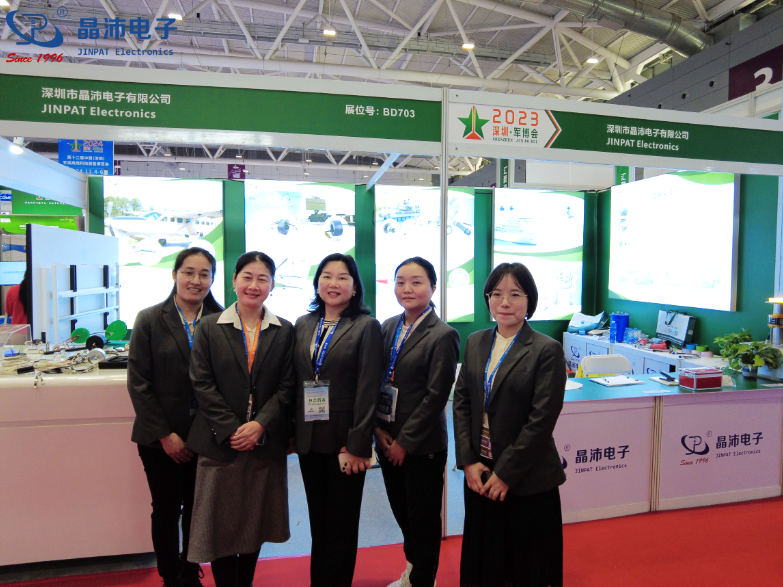

JINPAT is honored to be invited to participate in the 11th Shenzhen Military Expo , at the new venue of the Shenzhen International Convention and Exhibition Center. This Shenzhen Military Expo attracted over 500 exhibitors, and JINPAT is privileged to attend this event, collaborating with other exhibitors to explore new opportunities for industry development.

The Military Expo serves not only as a leading platform to showcase cutting-edge military technology and equipment but also as a vital arena for the exhibition, exchange, and learning within the civil-military integration industry. As a specialized slip ring manufacturer with robust technical capabilities, JINPAT has nearly 30 years of industry experience. With a dedicated team of nearly a hundred professionals in design,process engineering, experimental testing, quality control, and more, the company is committed to providing customers with outstanding personalized slip ring solutions and technical services.

During the exhibition, JINPAT enthusiastically engaged with fellow exhibitors to explore new opportunities for collaboration. Through the sharing of product case studies, the company showcased a series of innovative self-developed products, as well as application cases involving production equipment and testing stations. The diverse range of slip ring exhibits attracted a large number of users for consultation. Simultaneously, JINPAT arranged for its professional staff to provide detailed explanations, allowing users to gain a comprehensive understanding of JINPAT products and research capabilities. This facilitated a deeper appreciation and understanding of the company’s independently developed technologies, diverse product portfolio, and comprehensive service guarantees, providing audiences with a more intuitive understanding of JINPAT’s products, technologies, and solutions.

JINPAT has consistently adhered to the philosophy of “Crafting Quality with Ingenuity and Leading Change with Innovation,” and actively pursues the corporate vision of “Customer First, Quality First.” The company is dedicated to providing professional slip ring solutions for the global industrial system, playing a crucial role in supporting the accelerated development and high-end growth of the global information industry. Through this Military Expo, JINPAT showcased its independent research and innovation capabilities in different scenarios,highlighting the outstanding achievements of its products in practical applications. The company engaged in in-depth discussions with more partners and customers, collectively exploring the future development direction of slip ring technology. JINPAT will continue to strive, providing customers with more advanced and reliable slip ring solutions, contributing to innovation and development across various industries.