JINPAT Electronics is a dynamic slip ring manufacturer with an independent and experience R&D team. Since establishment, JINPAT has been devoted to bringing slip ring with better performance and quality.

For surveillance camera, JINPAT Electronics also provides innovative slip ring solutions. Generally speaking, JINPAT capsule slip ring that features mini size is sufficient for those camera system without specific requirements. However, in terms of surveillance camera that demand high speed data transmission while maintain high video quality, Ethernet slip ring is needed.

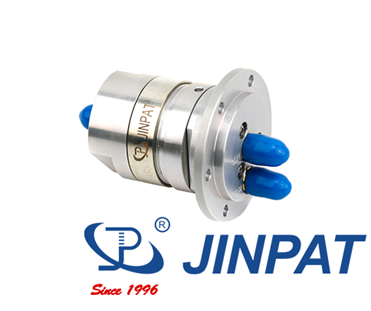

JINPAT LPC-24A-E4 is an Ethernet slip ring with 24 power/signal channels and 1 Gigabit Ethernet channel. This Ethernet slip ring is a specially improved version. Compared to the former slip ring models, this slip ring embraces a higher transmission rate and therefore able to transmit video data in a rapid way while ensuring a high video quality.

JINPAT capsule slip ring is perfectly fit for small applications like surveillance cameras, VR devices and handheld stabilizer. With capacity of transmission Ethernet signals, this mini size slip ring become a best choice for high and middle end applications.

Contact JINPAT Electronics for better slip ring models and custom solutions.