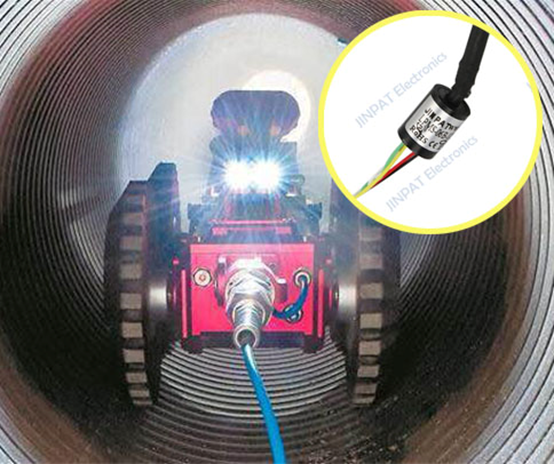

For fire trucks, cable reels, winches and cranes, most would demand rotary transmission of power and signals to fulfill their functions. A slip ring tends to be installed to allow a flexible movement of the machines while conducting power and signal transmission between the stationary part and rotary part.

JINPAT Electronics is an electronic component manufacturer rooted in slip rings, rotary joints and rotary unions. For engineering machinery, JINPAT also has exclusive and high-performing rotary solutions.

JINPAT engineering machinery slip rings feature compact structure design and easy installation. Given the special application category, these slip rings tend to be in higher protection level and with larger power capacity. With a protection grading of IP64, JINPAT slip rings for construction machines adapt perfectly to the shock-threaten and dusty environment. With special design, this kind of slip rings endure extreme temperatures, from -55 ℃ to + 80 ℃. Power capacity is 600A. The JINPAT slip ring takes up high shock-endurance structure design and can cope with the high vibration working environment. Thanks to the structure layout and the upper class material, JINPAT slip rings embrace stable operation and endurable product life.

JINPAT recommend through bore slip rings, the LPT series and high power slip rings LPA series to base your slip ring solutions for construction machine. For more solutions