OPTOELECTRONICS leads the future and drives application innovation! THE 25TH CHINA INTERNATIONAL OPTOELECTRONIC EXPOSITION will be held at the Shenzhen Word Exhibition and Convention Center from September 11th to 13th! JINPAT will be honored to participate in the exhibition with advanced technology and excellent products, and we sincerely invite you to visit!

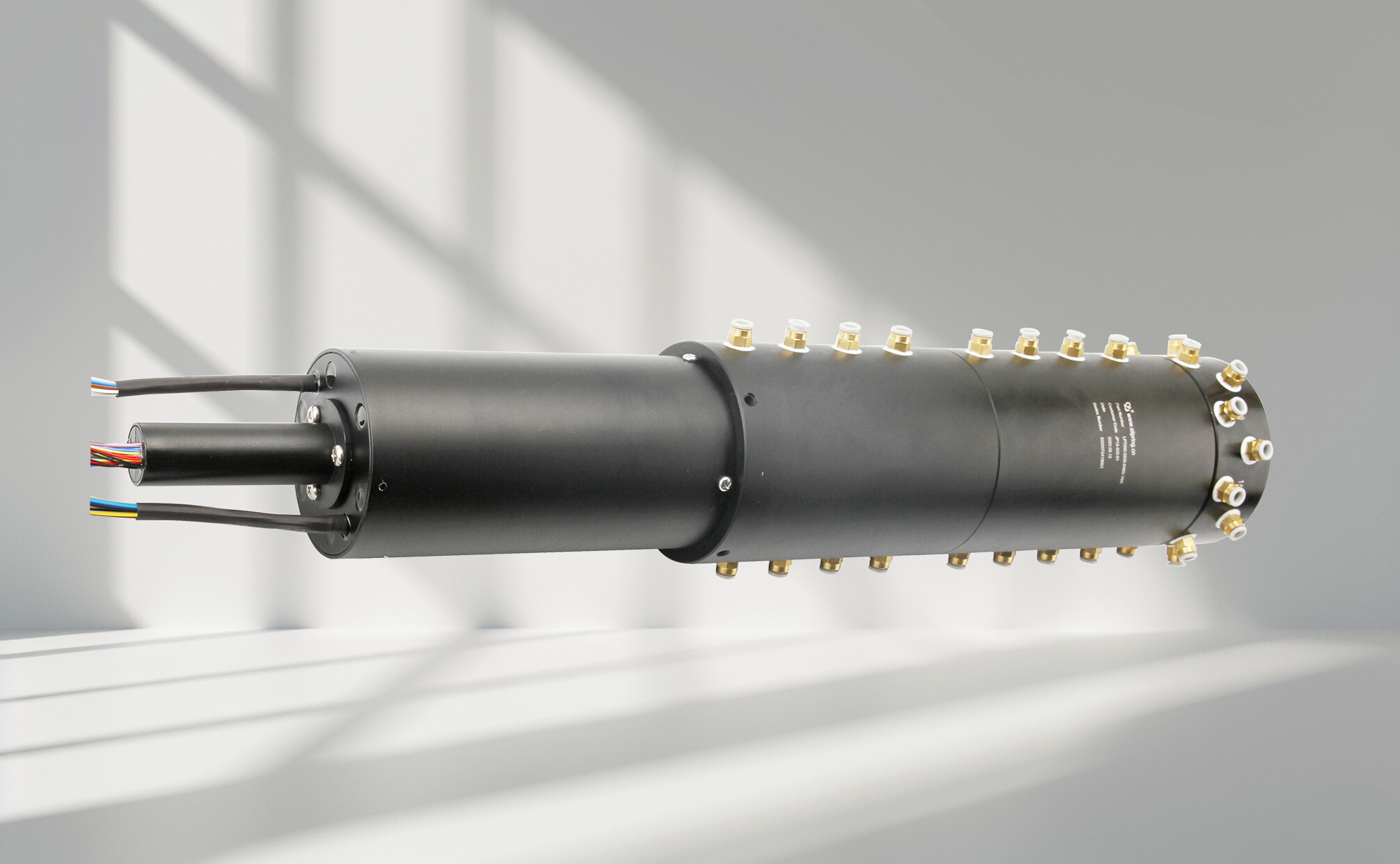

As a comprehensive exhibition covering the entire optoelectronic industry chain, CIOE brings together more than 3,700 high-quality exhibitors from more than 30 countries and regions around the world. As a professional slip ring manufacturer,JINPAT Electronics has nearly 30 years of industry experience and is committed to providing customers with excellent slip ring solutions and technical services. At this Optical Expo, JINPAT will showcase a series of independently developed innovative products and application cases such as production equipment and test benches through product case sharing.

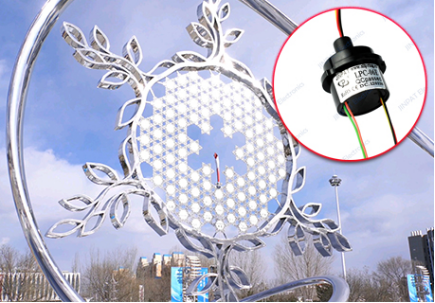

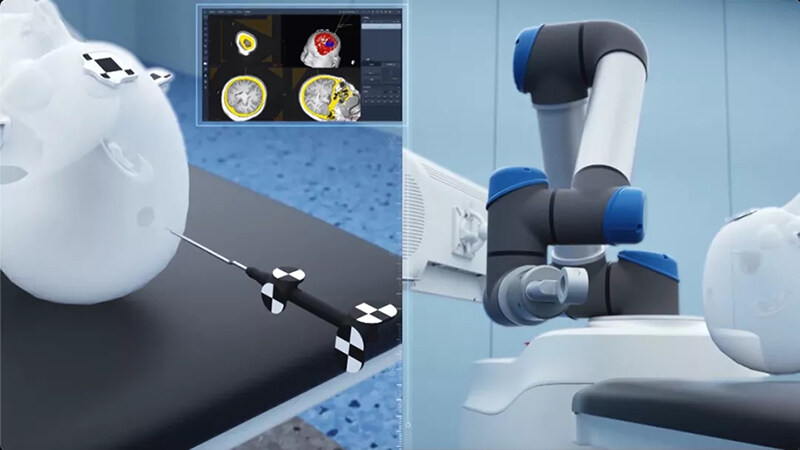

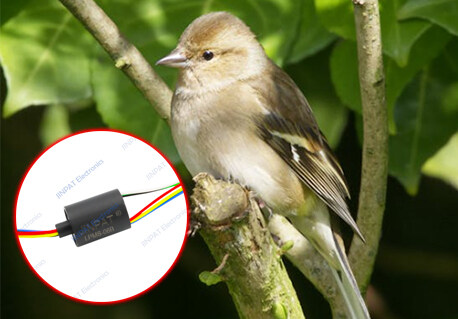

At this exhibition, our company will exhibit a series of representative product case sharing to show customers JINPAT’s independent research and development and innovation capabilities in different scenarios, as well as the outstanding achievements of its products in practical applications.

As a professional slip ring manufacturer with strong technical strength, JINPAT’s R&D team has nearly 100 engineers in professional design, process engineering, experimental testing, quality control, etc., and is committed to providing customers with highly personalized slip ring professional customization solutions.

JINPAT hopes to have in-depth exchanges with more partners and customers through this Optical Expo, jointly explore the future development direction of slip ring technology, and create a new chapter in the industry. Our company will continue to work hard to provide customers with more advanced and reliable slip ring solutions to help the innovative development of all walks of life!

Exhibition No.:10D155

Exhibition Time:September 11, 2024 – September 13, 2024

Exhibition Location:Shenzhen Word Exhibition and Convention Center

JINPAT sincerely invites you to visit the Shenzhen World Exhibition & Convention Center to witness JINPAT’s outstanding strength and innovative achievements in the slip ring field. Let us work together to create a better future and share success!