Medical equipment has always been representative of high-value products in the field of medical devices,especially devices like CT scanners. Like other industrial sectors, the medical device industry also relies on the support of numerous downstream industries.JINPAT, as a specialized slip ring manufacturer, is part of the medical device industry chain and has the ability to provide corresponding slip rings for various medical equipment with different functions.

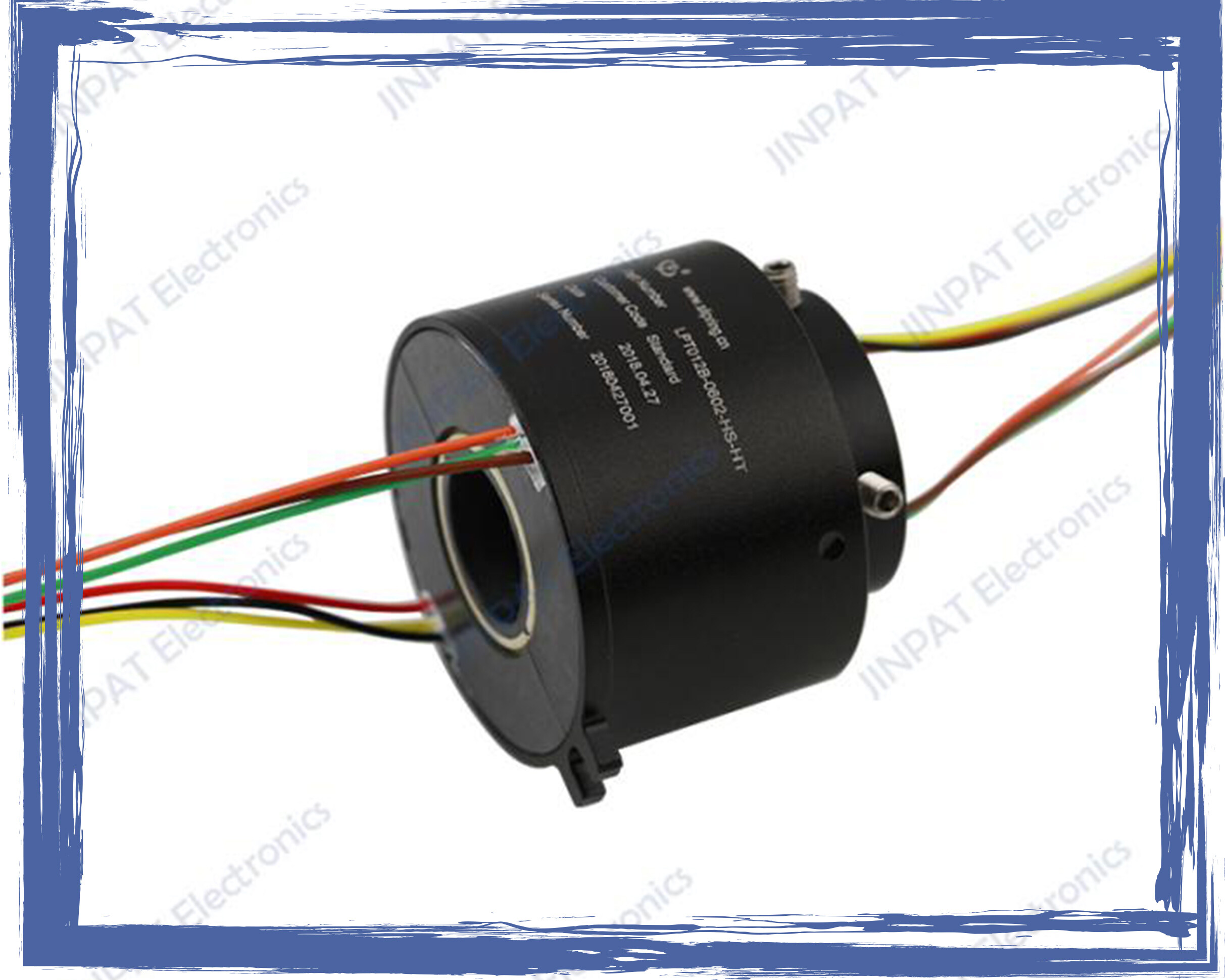

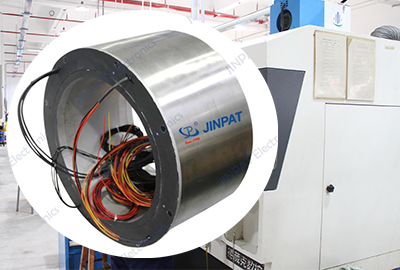

JINPAT has developed multiple types of slip rings for medical equipment. Apart from the large through-hole pancake slip rings with a diameter exceeding 1200mm developed for CT scanners, the rest of the slip rings are categorized as medium and small-sized products. Among these products, the capsule series slip rings are the mainstay, with only a few models belonging to the hollow shaft series. Whether capsule slip rings or hollow shaft slip rings, these products developed for medical equipment are primarily customized models. To meet the stability requirements of medical equipment, these slip rings use gold-to-gold contacts and have been optimized in certain performance aspects.

In some specialized medical equipment with unique functions, centrifuges or other high-speed systems are integrated, and the slip rings associated with these components are mostly high-speed products.Since the rotational speed of these components generally exceeds 500rpm,standard slip rings have a design speed limit of 300rpm, which is insufficient to meet the requirements. In order to address the needs of the medical industry and similar fields, JINPAT has developed the LPC/LPM-YS series of capsule standard slip rings. This series of products has a design speed of up to 2000rpm, meeting the requirements of the majority of medical or other high-end instrument equipment available on the market.

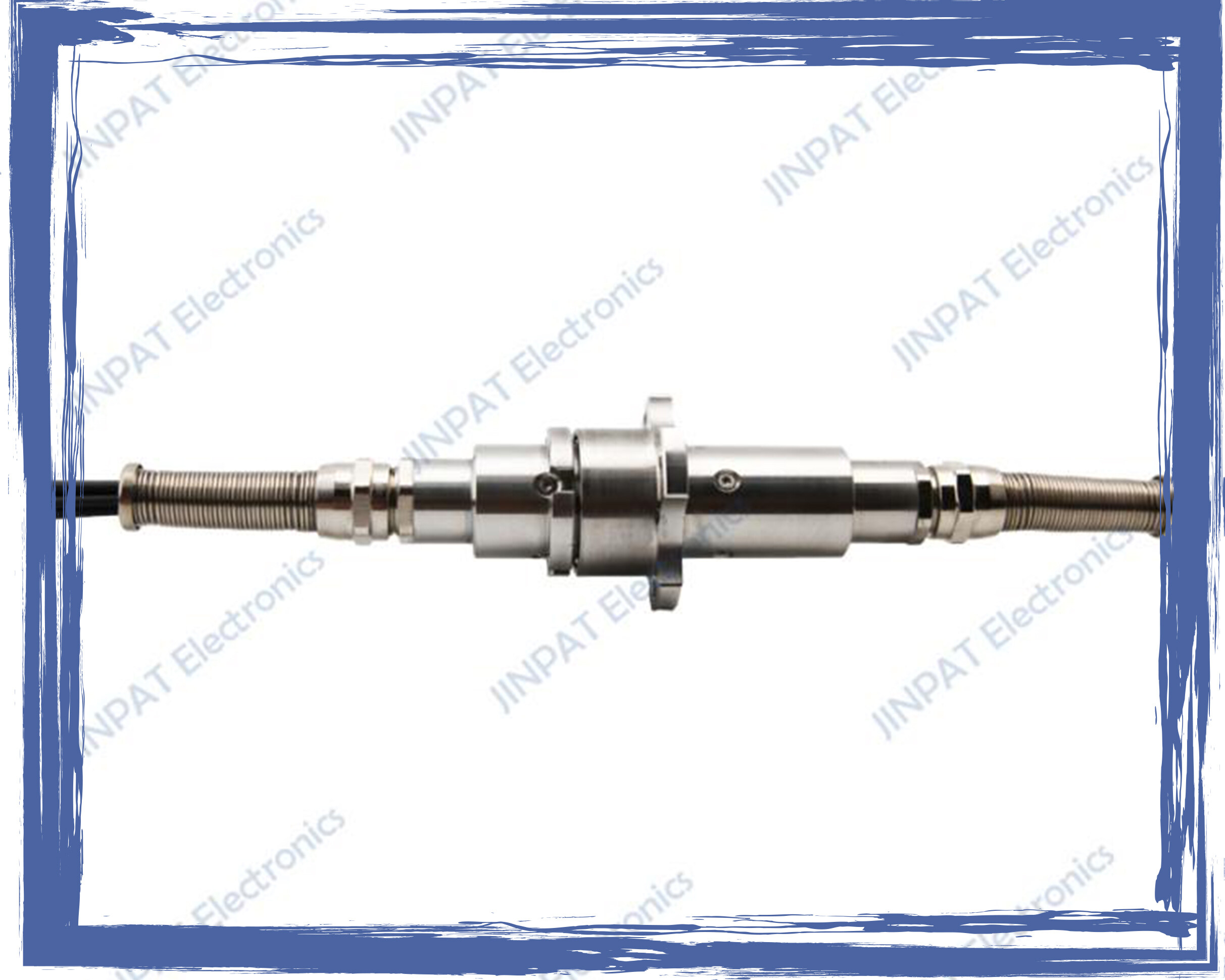

Compared to the capsule slip rings with an outer diameter of 22mm, hollow shaft slip rings have much larger copper ring diameters, which limits the transmission of certain special signals. However,this limitation is not significant in the field of medical equipment, as the most commonly used hollow shaft slip rings have a bore size of 12.7mm, and common signals in medical instruments such as USB 2.0, Ethernet, and pulse signals can be transmitted within this bore size. Hollow shaft slip rings also have an advantage in that the center through-hole can be utilized, and it can become an optoelectronic integrated slip ring after installing fiber optic slip rings. In many slip ring cases developed by JINPAT for medical equipment, there are also products with integrated single-channel fiber optic slip rings.